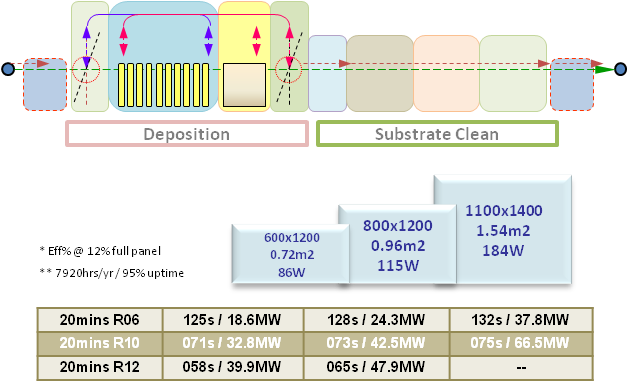

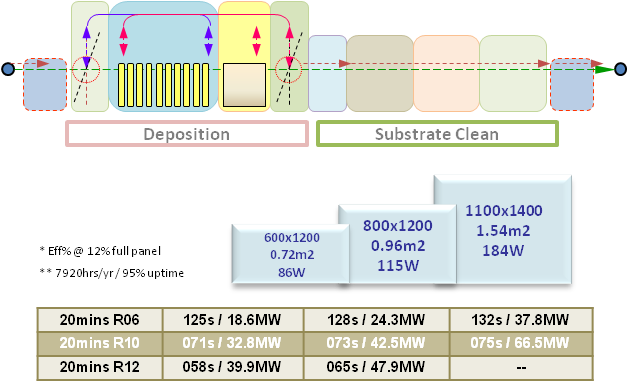

Wet Reactive (Chemical Bath Deposition) Coating System

PISCES (Glass CBD System)

CIGS Solar Cell Equipment Overview

CIGS Solar Cell Equipment Overview

CIGS thin film can dramatically reduce the cost of manufacturing solar cell with a high production yield. Started from 2004, Dalux has been focusing on research and manufacturing of the completed TURN-KEY system for CdS treatment, module plant production line and related products of CIGS solar cells equipment.

DALUX Perfornmence

.2005 Delivered over two digits of Dalux R2R-CdS Coater system worldwide, majorly in USA.

.2006 Delivered 3 lines of CIGS on Glass(CBD & KCN)

.2009 One full line wastewater treatment system started running in a CIGS factory

.2010 Around 200MW/a world wide of CIGS-PV produced via Dalux System

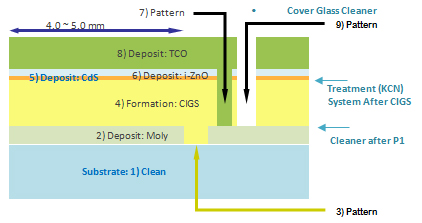

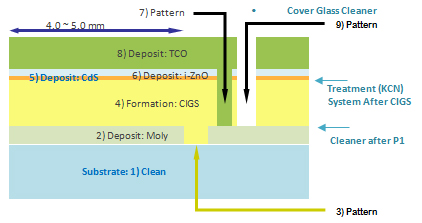

Typical CIGS Structure

.Before conducting the sputtering, substrate cleaning process can decrease the contact angle and ensure the quality of Mo layer.

.Through KCN micro-etching before the deposition of CdS thin film, it can decrease the roughness of CIGS surface and reduce the pin hole which may produce during the later CBD process.

.DALUX equipment, CBD Coater, applies the technology of Chemical Bath Deposition (CBD) to coat nano thin films on the substrates of glass and foil.

.During the CBD process, the CdS thickness and uniformity can be controlled by adjusting the distribution of flow rate, density and temperature.