Capacity Type TP Equipment

Touch Panel (Glass Process)

Dalux provides equipments for wet process of touch panel, including the processes of developer, etching, stripper, cleaner and automation, which can apply to R2R Film Type and Glass Type touch panel.

%E6%BF%95%E8%A3%BD%E7%A8%8B%E8%A8%AD%E5%82%99-en.jpg) Touch Panel Equipment Overview

Touch Panel Equipment Overview

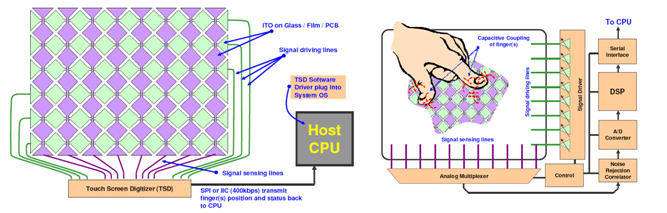

Touch panel can be categorized to Resistance/Capacity / Projective Capacitive /Sonic/ Optical / Electromagnetic types. The processes of producing touch panel vary by different substrate material. Dalux provide turn-key planning and production line equipment for resistance and capacity touch panel process, and has accumulated rich experiences since 2006. Our performance include whole plan plant manufacturing of G2.5, G4.5 D.E.S Line, G5.5 D.E.S Line, G3.5 capacity type, Capacity type R2R Film.

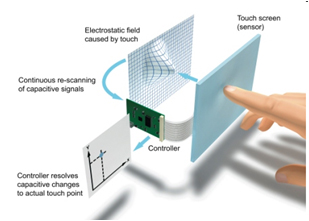

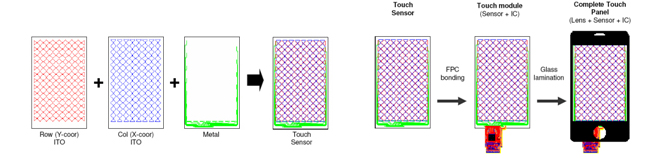

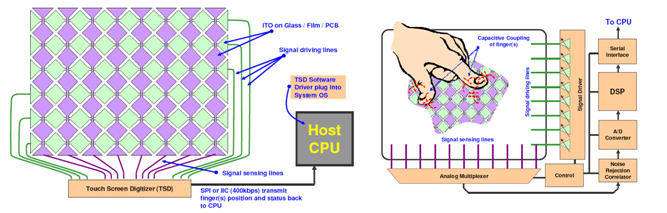

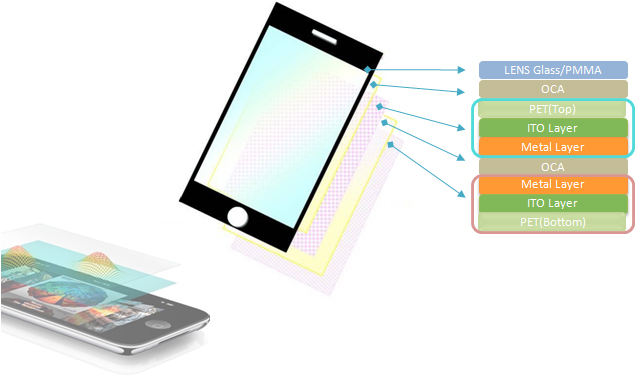

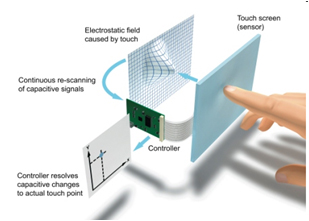

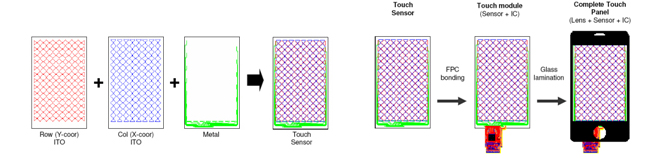

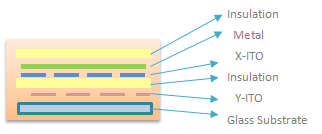

Typical Touch Panel Structure (Capacity Type)

Typical Touch Panel Structure (Capacity Type)

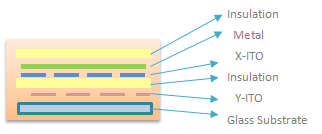

Cross Section

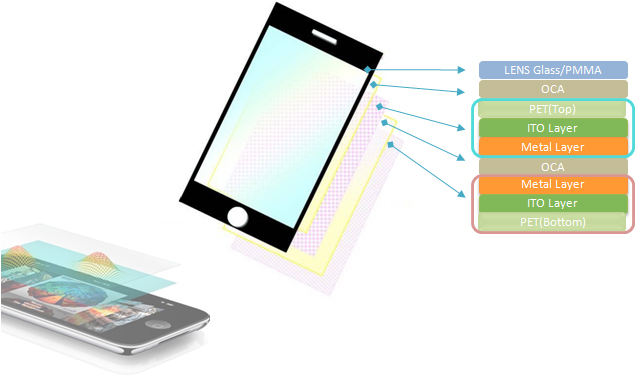

Film To Film Touch Panel Stack Up Construction

%E6%BF%95%E8%A3%BD%E7%A8%8B%E8%A8%AD%E5%82%99-en.jpg)